A NAR L3 Certification Rocket

Copyright © 2008 Bdale Garbee

This document is released under the terms of the Creative Commons ShareAlike 3.0 license.

| Revision History | |

|---|---|

| Revision 1.0 | 15 November 2008 |

| Successful certification flight at Hudson Ranch | |

| Revision 0.2 | 28 October 2008 |

| Revising during flight to DC | |

| Revision 0.1 | 23 October 2008 |

| Initial content, derived from YikStik | |

Table of Contents

This is a rocket I'm building for my second attempt at a NAR Level 3 certification flight. It's basically a Polecat Aerospace Goblin 10 kit augmented with an additional electronics bay in the nose cone, some structural reinforcement, and incorporating a few personal build preferences.

Preliminary analysis suggests that it should reach just under 7k feet on the Aerotech M1297W reload, and could break two miles on the Cesaroni M795W moon-burner. This means that a certification flight can be supported at Hudson Ranch with the standing 8k waiver, at the Tripoli Colorado site under their higher-altitude window, or at either of the NCR launch sites under their standing waivers. The smallest reasonable motor for this rocket would be a Cesaroni K445 or equivalent, which would yield an apogee of about 2300 feet.

Table of Contents

The Goblin 10 kit is a simple "four fins and a nose cone" rocket that is short and squat, with a 98mm motor mount. It supports dual-deploy by using the forward end of the long motor mount tube to hold the main. The primary electronics bay is between the forward two motor mount centering rings, accessed by a side hatch. An additional payload bay will be built inside the nose cone to carry experimental altimeters, a tracking beacon, and possibly a GPS position reporting system.

I will include 8-24 T-nuts in the aft centering ring spaced to allow the use of an Aeropack 98mm retainer and associated 75mm adapter.

Instead of using the supplied nose cone bulkhead, I intend to cut a custom one that would support installing a length of 98mm motor mount from the tip of the nose to the bulkhead. With a plate cut to cover the aft end of the airframe tube, this would form an electronics bay capable of holding a beacon transmitter, GPS system, or other custom electronics.

The recovery system will feature dual redundant barometric altimeters in the main avionics bay between the two forward motor mount centering rings.

A PerfectFlite MAWD will be flown as the primary altimeter and to record the flight altitude profile. A MissileWorks Mini-RRC2 will fly as backup altimeter and to directly capture max velocity.

Each altimeter will have a separate battery and rotary power switch. A third rotary switch will be used as a SAFE/ARM switch configured to interrupt connectivity to all ejection charges in accordance with NAR certification requirements.

The Goblin 10 kit designers indicate that the rocket is unconditionally stable with all motors that fit the motor mount geometry. Since we're adding mass at both ends, by putting a payload in the nose cone and by glassing the fins, the overall stability of the design should be retained, but simulation to confirm that seems prudent.

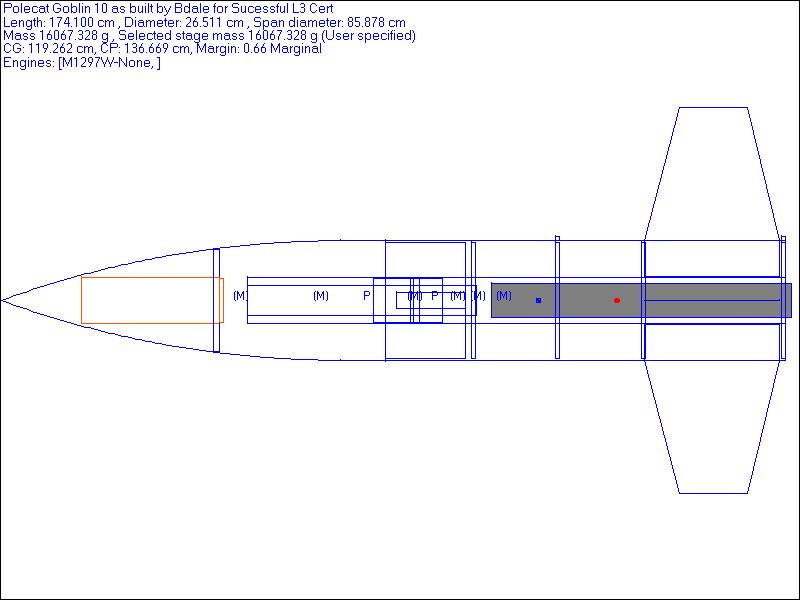

Thorough analysis using RockSim with various motors ranging from the Cesaroni K445 through the Aerotech M1939W always shows the stability as marginal. This is typical of short fat rockets that don't meet normal length to airframe diameter ratio expectations. Given this, I take the fact that RockSim shows the stability as marginal instead of unstable as strong evidence that the rocket will in fact be stable in flight. I also note that the simulated margin of stability in my as-built configuration is fairly close to the margin of stability of the as-designed model.

The Aerotech M1297W reload should carry this vehicle to just under 7000 feet AGL from Colorado Front Range launch sites. It should reach just over 2 miles on a Cesaroni M795 moon burner or equivalent.

The recovery system will use dual redundant barometric altimeters firing 4F black powder charges using commercial e-matches. At apogee, a drogue chute will deploy with separation of the nose cone. A Giant Leap TAC-1 36 inch chute already in hand will serve as the drogue. At a preset altitude, a main chute will be deployed from the forward end of the motor mount tube to achieve recovery of the bulk of the rocket at approximately 20 ft/sec.

I intend to sew the main parachute from scratch with my wife's help using a design documented by Team Vatsaas using 1.9oz rip-stop nylon and 550 lb parachute cord. The anticipated build weight implies that a 10 foot parachute would be appropriately sized.

The recovery system attachment points will all use 1/4 inch u-bolts with nuts, washers, and backing plates through bulkheads.

Table of Contents

I have collected all of my build photos in one place, they may show better than I can explain how various aspects of the Goblin went together.

The airframe tubing provided in the Polecat kit is thick cardboard tube with a thin exterior fiberglass wrap. To increase airframe strength, and particularly to prevent zippers, additional reinforcement seemed warranted.

The inner layer of paper was removed from the front 9" or so of the tube. The tube was soaked with West Systems epoxy diluted with about 20% by volume with acetone, and then a carbon fiber wrap was applied to the interior front of the tube and held in place during curing by an inflatable child's bounce toy inside a plastic garbage bag. The result is a substantially strengthened tube, with carbon fiber lining from the leading edge back past the first centering ring.

The provided nose cone bulkhead was replaced by a custom centering ring cut from 3/8 inch birch plywood. The ring's outer diameter was adjusted put place the ring approximately an inch forward of the end of the motor mount tube, and the inner diameter was cut to fit Giant Leap 98mm phenolic airframe tubing. A length of such tubing was cut to fit inside the nose cone and extend back to flush with the trailing edge of the ring. The centering ring was drilled and fitted with two u-bolts for recovery system attachment and four 6-32 T-nuts to hold a payload mounting plate in place over the aft end of the 98mm tube.

The airframe tubing was glued into the tip of the nose cone with West Systems epoxy using both milled glass and microlite filler to thicken the mix. The centering ring was then epoxied in place using a similar mix around the outer edge to form a heavy fillet and 5-minute epoxy to the piece of airframe tubing. After the epoxies cured, a rotary tool was used to cut the airframe tubing off flush with the aft surface of the centering ring.

The avionics bay walls were installed approximately 90 degrees apart prior to installation of the motor mount assembly in the airframe. The airframe wall was marked for a 3.5 x 6.5" access hatch centered over the bay 90 degrees from the rail button line. This allows sufficient room to install the switches on one side of the hatch yet still inside the bay, and to place the static vent on the other side of the hatch so that there will be minimal effect from air disturbed by movement over the hatch cover edges.

Rails were fabricated from 3/8" birch plywood and 6-32 blind nuts to allow for a removable avionics sled, rectangular, with 4 screws to hold the sled in place. A suitably sized avionics sled should be possible to install and remove through the avionics bay hatch allowing for possible future experiments with alternative avionics.

Table of Contents

This rocket uses dual deployment.

The apogee event separates the nose cone from the airframe. The nose cone is attached to the airframe with a length of heavy-duty tubular nylon shock cord. A drogue chute protected during ejection by a kevlar blanket is attached to the shock cord close to the nose cone end.

The main is a 10 foot chute sewn from the design documented by Team Vatsaas. It is held in place prior to ejection by a layer of paper taped over the front of the motor mount tube. At ejection, a piston pushes the chute forward through the paper and ejects it from the rocket. This chute is attached to the airframe through an additional length of heavy-duty tubular nylon shock cord.

Depending on the results of ground testing, the main chute may be packed in a Giant Leap kevlar deployment bag attached at the main chute apex, with a smaller drogue chute deployed to pull off the bag and cleanly deploy the main. The primary motivation for this is to prevent the main chute shrouds from tangling during ejection.

The main avionics bay between the forward two centering rings is populated with two commercial altimeters, a PerfectFlite MAWD and a Missile Works miniRRC2. Each is powered by a dedicated 9V alkaline battery, and has a dedicated on/off power switch mounted for access from outside the rocket. Additionally, a single safe/arm switch with two poles is used to interrupt the return circuits from the igniters to each altimeter. See the attached schematic of the avionics bay contents for more details.

Details of ejection charge design goes here.

The Info Central Black Powder Sizing page is the most authoritative site I've found on this topic. The formula they suggest is diameter in inches squared times length in inches times a coefficient in grams of black powder. For the main charge, which will be in the 98mm motor mount tube, a pressure of 15psi is appropriate giving a coefficient of 0.006. For the drogue charge, which will be in the main airframe, a pressure of 5psi is more appropriate, leading to a coefficient of 0.002.

The drogue bay is 10 inches ID at the widest point, but contains the protrusion of the main bay and a decreasing radius in the nose cone. Thus some fudging on the length is appropriate, and we will use 18 inches. That works out to 3.6 grams of BP. This rocket will not fly high enough for there to be a significant effect on BP burn characteristics, so no special compensation should be required.

The main bay is 3.9 inches ID and perhaps as much as 24 inches long depending on which motor is selected. That works out to 2.2 grams of BP.

Ground testing yielded 3.5 grams for the apogee charge and 1.5 grams for the main. Backup charges will contain additional BP in accordance with the "blow it off or blow it up" philosophy.

With a 10 foot Team Vatsaas design parachute and our anticipated build weight, the descent rate under main should be just over 20 feet per second.

-

Planning

1.1. Pick a club launch with suitable waiver and facilities to support flight. 1.2. Confirm L3CC member(s) available to attend selected launch. 1.3. Confirm that required loaner motor hardware will be available at launch. 1.4. Notify launch sponsor (club president) of intended flight. 1.5. Notify interested friends of intended flight. 1.6. Perform final pre-flight simulation with as-built masses, etc. 1.7. Gather consummables and tools required to support flight 1.7.1. fresh 9V batteries 1.7.2. black powder 1.7.3. e-matches 1.7.4. motor retainer and adapter parts 1.7.5. small nylon wire ties 1.7.6. cellulose wadding material 1.7.7. masking tape 1.7.8. screwdriver for phillips-head avionics bay screws 1.7.9. small straight-blade screwdriver for power switches 1.7.10. motor reload kit (or arrangements to procure at launch) 1.7.11. high temperature grease 1.7.12. long small diameter dowels for igniter insertion -

Before Leaving Home

2.1. program altimeters for suitable mach delay and recovery deployment -

MAWD

- no mach delay

- 1300 foot main deploy

-

miniRRC2

- no mach delay

- 1000 foot main deploy

- 2 seconds apogee delay

- no main delay

- dual deploy

- ops mode 16 (default)

2.2. assemble all recovery system components and ensure everything fits 2.3. confirm wiring and operation of altimeter power and safe/arm switches 2.4. Ground test recovery system to confirm suitable black powder charge sizing -

MAWD

-

Pre-Flight

3.1. confirm payload batteries in good condition, bay loaded, power switch works 3.2. confirm reception of signals from transmitter(s) 3.3. install fresh 9V batteries for altimeters on avionics bay sled 3.4. inspect altimeters and associated avionics bay wiring for visible faults 3.5. close up avionics bay 3.6. build and install BP charges 3.6.1. Drogue Primary Charge - 3.5 grams 4F BP 3.6.2. Drogue Backup Charge - 4.0 grams 4F BP 3.6.3. Main Primary Charge - 1.5 grams 4F BP 3.6.4. Main Backup Charge - 2.0 grams 4F BP 3.7. fold main chute, connect recovery harness to piston and airframe, install in MMT and tape paper over the front end 3.8. fold drogue chute into a kevlar pad, connect recovery harness to nose cone and airframe, install in airframe 3.9. power up payload using switch on base plate in nose cone, then install nose cone, using masking tape to adjust fit as required 3.10. safely power up altimeters, operate safe/arm switch, and confirm e-match continuity 3.11. safe and power-down the altimeters 3.12. load motor per manufacturer instructions 3.13. install motor in motor mount 3.14. install motor retention 3.15. prepare igniter using e-matches, 1/8 inch dowel 3.16. confirm all screws in place, avionics off and safe 3.17. fill out a launch card 3.18. notify RSO/LCO of readiness for inspection and launch, obtain a rail assignment and permission to move rocket to launch pad for final prep 3.19. coordinate readiness with support team members, photographers, observers -

Final Prep

4.1. move rocket to launch area 4.2. clean and lubricate launch rail if necessary 4.3. confirm reception of signals from payload transmitter(s) 4.4. mount rocket on launch rail, rotate to vertical 4.5. power up primary altimeter, confirm expected beep pattern 4.6. power up backup altimeter, confirm expected beep pattern 4.7. arm ejection charges 4.8. confirm altimeters both giving expected beep patterns for igniter continuity 4.9. install igniter and connect to launch control system 4.10. capture GPS waypoint for rail location 4.11. smile for the cameras, make sure we have enough "foil Murphy!" shots taken 4.12. retreat to safe area behind LCO 4.13. confirm continued reception of transmitter signal(s) from payload bay 4.14. confirm photographers and observers are ready and know what to expect 4.15. make sure binoculars and backpack with water and recovery tools are at hand 4.16. tell RSO and LCO we're ready to launch 4.17. try to relax and enjoy watching the flight! -

Recovery

5.1. track rocket to landing site 5.2. capture GPS waypoint of landing site, take lots of photos 5.3. note any damage 5.4. gather up and roughly re-pack recovery system for return to flight line 5.5. bring the rocket to observers for post-flight inspection

A successful level 3 certification flight occurred on 15 November 2008 at the SCORE Hudson Ranch launch facility. The motor was an Aerotech M1297W provided by Tim Thomas of Giant Leap Motors, the igniter was assembled by James Russell using his special thermite mixture, and numerious SCORE, COSROCS, and NCR members were present to assist with the launch! Great weather for November... mostly clear and sunny, light winds, dry ground, temps above freezing.

The motor came up to pressure very quickly and the rocket leapt off the pad, climbing smoothly under power and then doing about two slow rolls during the coast phase. Deployment of the nose cone and drogue occurred as planned when the primary apogee charge fired. Unfortunately, the main deployed around the time the backup apogee charge fired, so the descent was under main from apogee. Fortunately, the winds were low enough and the descent rate high enough that the rocket touched down without damage within the waiver area for a successful certification!

The rocket weighed 25.2 pounds prepared for launch without the motor. The motor weighed about 10.25 pounds, which included about 6 pounds of propellant. Thus the descent mass under chute was just over 29 pounds. The miniRRC2 altimeter reported 5949 feet apogee, 980 feet per second max velocity, and 19 seconds to apogee. The MAWD reported 5953 feet apogee.

The ascent was straighter than expected... very smooth during the motor burn, then a couple slow rolls during coast. The two altimeters agreed within 4 feet on the apogee. The max velocity recorded is a little higher than predicted by simulation, but the accuracy of that measurement is likely limited since it is based on pressure data.

I was able to watch the apogee events through binoculars, and could clearly see the main deploy as the backup apogee charge fired. I saw some evidence of tearing of the paper taped over the motor mount to retain the main chute during ground testing, so assume this was the root cause of the early deployment. When the backup apogee charge fired, the shock cord was not yet in tension, and thus the charge probably kicked the airframe backwards hard enough to allow the main chute to slide out through the torn paper and deploy. The best fix for this might be to fabricate a second piston to use as a cap and retain it with two shear pins. This would be much less likely to prematurely deploy than the current taped paper approach.

The most significant variance from expectation was the descent rate. The spreadsheet provided by the Team Vatsaas folks for their design suggested we'd see around 21 feet per second. Analysis of the flight profile from the MAWD shows that our actual descent rate was about 32 feet per second. There are three possible sources of error to consider.

- The first is descent mass. Pre-flight calculations used 25 pounds. The actual flight weight was 25.2 pounds plus the burn-out weight of the M1297W, which should be about 4.5 pounds. That yields 29.5 pounds total. All pre-flight calculations were done using 25 lbs, with the thought that the motor mass might cancel out against the drag provided by the drogue. In flight, it appeared the drogue supported the nose and the main supported the fin can with very little interaction between the two.

- Second, the dimensions given by Team Vatsaas' spreadsheet for the pattern grid seem small. For a 10 foot chute, they suggest a grid size of 5 inches, which looks more like an 8.5 foot finished chute size to me.

- Finally, the Cd in the spreadsheet is 1.5, which may be overly optimistic.

My calculations show that if we assume a chute size of 8.5 feet and a Cd closer to 1, we can get to a descent rate of 32 feet per second.

So, overall, this was a successful flight, but with three things to change before we fly the airframe again...

- the main chute may be too small

- switch to a piston to cap the main chute bay

- beef up the battery retention on the avionics sled