Test 5

Trying again using KNSO with our new casting bases. We also have a real eye-dropper now for measuring the surfactant. 4 38mm grains of 1.875" length, 250 gram batch using formula of

- 65% KNO3, 162.5g

- 35% Sorbitol, 87.5g

- 1% red iron oxide, 2.5g, added after melt

- 3 drops Polystep-B1, added before pour

Process

The multi-cooker was preheated to about 250F with the lid on. Temp was increased during melting to 275F indicated.

Individual casting tubes with fill marks, coring rod inserted after pour, cap installed and grain tapped down.

Results

- Grain 1, 51.56g net

- Grain 2, 52.80g net

- Grain 3, 52.30g net

- Grain 4, 51.23g net

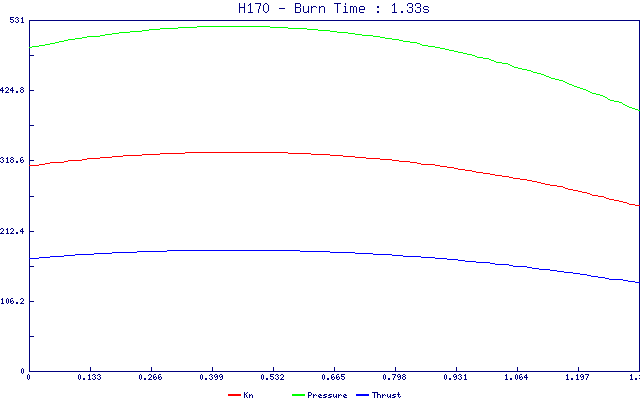

Simulation

Propellant : propellants/knsb.xml Nozzle diameter : 0.739 cm (0.291") (19/64") Number of grains : 4 L/D ratio : 5.550 Port-to-throat ratio : 2.952 Mass Flux : 1.374 lbs/inch^2 Mach number : 0.697 Propellant length : 18.440 cm (7.260") Web Thickness (max) : 1.026 cm (0.404") Burn rate : 0.773 cm/s (0.304"/s) (a=7.852mm/s; n=-0.013) Total propellant weight: 216.00 g (7.619 oz/0.476 lbs) Average grain weight : 54.00 g (1.905 oz) Theoretical density : 1.841 g/cm3 (0.067 lb/in3) Actual density : 1.582 g/cm3 (0.057 lb/in3) Density ratio : 85.953% Specific impulse (Isp) : 106.342 s (estimated) Initial Thrust : 169.37 N (38.08 lbs) Peak Thrust : 182.21 N (40.96 lbs) at 34.00% (0.45 s) Kn Ini : 309.48 (488.04 psi) Kn Max : 330.39 (520.59 psi) Kn Fin : 248.87 (393.56 psi) Kn Avg : 309.70 (488.40 psi) Total Impulse : 225.104 Ns (40.69% H) Burn Duration : 1.328 s Average Thrust : 169.555 N Motor : H170

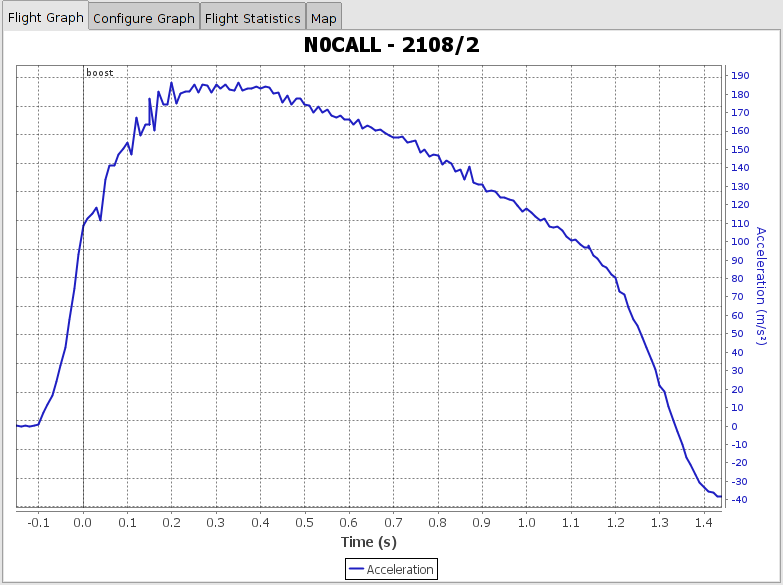

Flight Test

These four grains were assembled in an AT 38/480 case with a random AT delay grain from the pile of left-overs, and flown in Robert's Madcow Little John at Tripoli Colorado Spring Fling 2015. We used a Slim Gem igniter from Quickburst. Great flight! The motor seemed to come up to pressure quickly, and burned brilliantly.

The airframe weighed 1200 grams ready to launch, and 982 grams post-flight, of which 1g or so was BP in the ejection charge, and a few grams were in the Aerotech delay grain.

Post-flight measurement of the phenolic nozzle showed approximately an 0.330" throat, which clearly indicates some erosion from the 0.291" starting point.

Observations

Pour went really smoothly. Easier than previous batches, perhaps due to a bit more surfactant, perhaps just getting better, perhaps due to putting the mandrels in post-pour. One grain looked "perfect" with the propellant settled evenly and a couple mm of open gap at the top of the casting tube. We think this one may have been slightly under-filled compared to the others, all of which had some evidence of propellant sticking to the cap and leaving an uneven top surface. This resulted in some quick trim work with a knife, ergo final grain masses not matching all that well.

We were totally stoked that the burn time matched simulation (once we factor in a tenth of a second or two before the motor came up to pressure!). We were also pleased that the max pressure was "right on time" at about 0.4 seconds after coming up to pressure. The regressive curve seems a bit exagerated in the flight accel data, which seems completely explainable by the nozzle throat erosion causing pressure to faill during that period.

The airframe saw an average of 12 G acceleration on the way to Mach 0.6 and 2838 feet above the laucnh site which is at 8800 feet MSL. Perfect recovery! Pretty cool for our first real flight test!